Marine Equipment NATIONWIDE

Expert Solutions for Machinery & Equipment

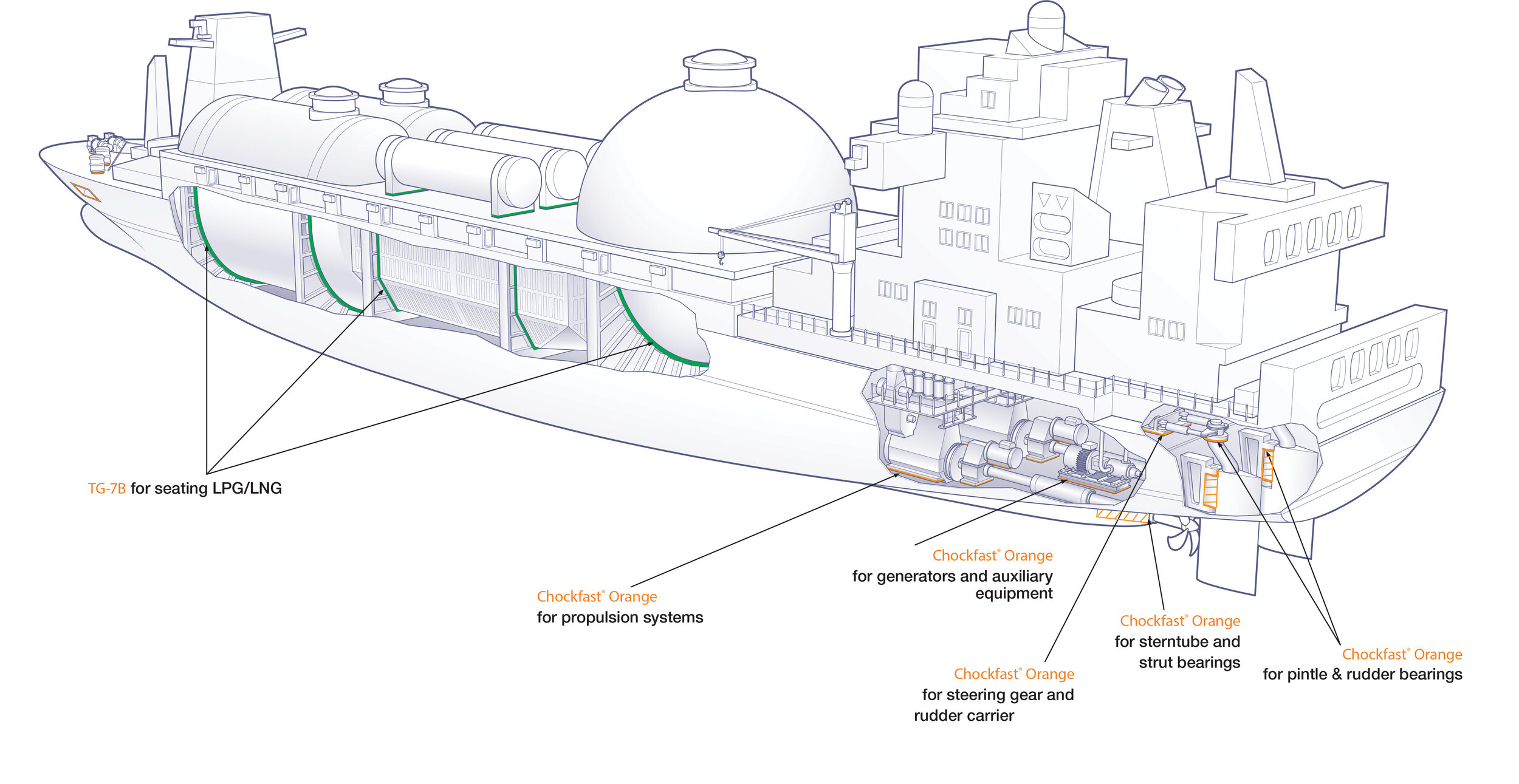

As pioneers of resin chocking systems for installing critical machinery onboard oceangoing vessels, our Chockfast products are the industry standard for chocking of Main Engines and Propulsion Systems. We continue to provide the marine industry with time proven solutions that ensure cost and process efficiencies using high performance polymers.

The right grouting system, as part of a well engineered equipment system, can provide years of cost effective, reliable performance. The “Chockfast System” supports more horsepower than any other system. From thin pour epoxy chocks to large foundation repairs, Chockfast has the properly engineered system for all your critical equipment needs.

CHOCKFAST ORANGE: the reliable, poured-in-place, epoxy resin chocking system used to install more than 50,000 main propulsion engines plus auxiliaries over a 50 year period.

Chockfast Orange Chocking Compound

Chockfast products for chocking marine engines, propulsion systems and sterntube applications.

The Main Engine is the most expensive, most important and hardest working component on any ship. To keep a vessel at sea running smoothly, maintaining the precise alignment of the Main Engine with the Propulsion System is critical.

The excellent structural properties of Chockfast Orange enable it to hold the precise alignment of such critical machinery throughout its working life. This reduces the risk of breakdowns by minimizing wear and tear of seals, bearings and couplings thereby reducing the operating cost of the vessel.

Approved by all major Classification Societies, Chockfast Orange provides a convenient chocking solution for all types of machinery and equipment. The formulation is designed to be user friendly. The quantity of hardener mixed with the resin can be adjusted to varying conditions of steel temperature and chock thickness, making it easy to use in hot and cold weather.

TG-7B EPOXY MASTIC & LIQUID

As the demand for clean fuel continues to rise, so does the market for LPG and LNG carriers. These specialized vessels hold large tanks that carry the liquefied gas in cryogenic conditions.

The cryogenic tanks are primarily supported by wooden blocks made of a special grade of laminated wood. TG-7B, in paste or liquid form, is used at the interface between the wood and the tank to create a uniform load bearing surface under the tank.

In addition to its load bearing capability, TG-7B withstands seawater and hydrocarbon vapours, making it suitable for this application. This two-component epoxy mastic/liquid can resist temperatures ranging from -165°C to +40°C while accommodating the thermal contraction and expansion of the tanks in service.

TG-7B APPLICATION AREAS

TG-7B is designed to be applied on or under the supporting wooden components in the mounting of all types of LPG/LNG tanks including sliding and fixed support, anti-floating chocks and anti-rolling chocks

Chockfast Orange Application